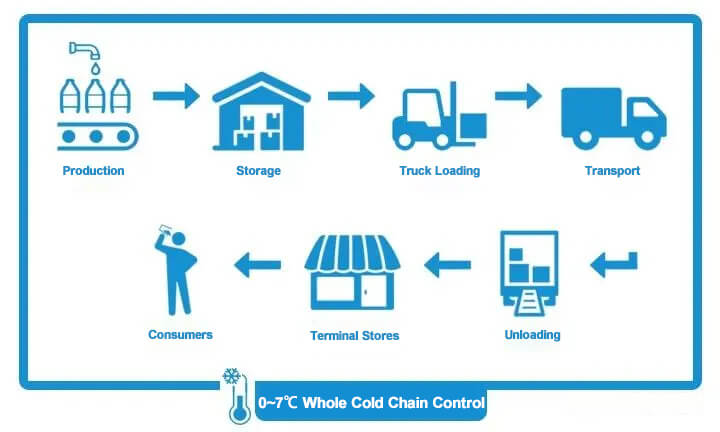

The distribution of temperature-sensitive products like vaccines relies heavily on an unbroken cold chain. Internet of Things (IoT) technology is transforming this space by enabling real-time monitoring of environmental conditions throughout the supply chain. IoT sensors placed in transportation units and storage facilities can continuously track temperature, humidity, and location. When thresholds are breached, automated alerts notify stakeholders instantly, allowing for immediate corrective action. This level of visibility significantly reduces spoilage, ensures regulatory compliance, and maintains the integrity of critical medical supplies.

One key advantage of IoT in cold chain logistics is predictive maintenance and operational efficiency. Connected systems analyze trends to anticipate equipment failures before they occur, minimizing downtime and preserving product quality. Moreover, cloud-connected dashboards allow logistics managers to track multiple shipments in real-time, improving decision-making and reducing human error. These improvements lead to lower operational costs and increased reliability—essential in high-stakes industries like pharmaceuticals.

The integration of IoT in vaccine distribution has proven especially crucial during global health crises. During the COVID-19 pandemic, for instance, ensuring the correct storage temperature of vaccines like Pfizer’s—requiring -70°C—was vital. IoT-driven cold chain solutions enabled governments and healthcare providers to maintain quality across vast distances and varying climates. As vaccine technology and distribution expand, IoT’s role will only grow in supporting safe, efficient, and transparent global health operations.